In addition to a comprehensive suite of commercially-available NDT and SHM systems, Guidedwave continues to pioneer new technologies that utilize ultrasonic guided waves. A few examples of our technologies that are still under research and development are:

Ultrasonic De-Icing

Ultrasonic de-icing is non-thermal and consumes much less power than comparable electro-thermal blanket systems. It is also safe for composite materials that may be damaged by thermal de-icing methods.

Learn More

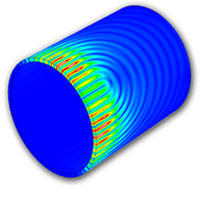

Pigging Technologies

Non-contact, EMAT generated guided wave ultrasound is a promising technology for the detection of coating disbondments, cracking, and corrosion.

Learn More

Rail Inspection

Guided waves are optimal for detecting transverse defects in rail, which are a critical type of defect that is very difficult to detect using traditional ultrasonic rail inspection techniques.

Learn More

Ice Sensing

Guidedwave’s ultrasonic ice sensing solution requires no hazardous materials, can be delivered at a substantial cost savings to other alternatives, and can deliver excellent sensitivity.

Learn More

Nonlinear Guided Waves

Nonlinear ultrasonic guided waves are known as one of the best approaches for characterizing changes in dislocation density and slip bands that precede the initiation of a fatigue crack.

Learn More

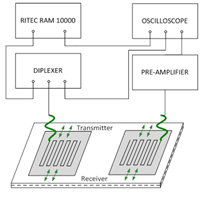

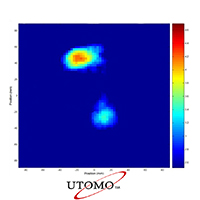

Guided Wave Tomographic Plate/Shell Monitoring System

UTOMO technology was developed specifically for large-area structural health monitoring (SHM) of aircraft components to eliminate the need for expensive, time-consuming, localized inspections.

Learn More