Aircraft icing is a critical concern for rotorcraft and fixed wing aircraft in both the military and civilian domains. In-flight icing on aerodynamic and control surfaces can lead to dramatic losses in lift and control and have caused hundreds of accidents and more than a thousand deaths in the past few decades. Various types of ice protection and sensing systems exist, but each has its own drawbacks such as weight or power consumption. Ultrasonic de-icing, a method developed by Penn State University and Guidedwave, utilizes ultrasonic vibration to fracture and delaminate ice accreted on an aircraft structure such as a wing leading edge or an engine inlet. Ultrasonic de-icing is non-thermal and consumes much less power than comparable electro-thermal blanket systems. It is also safe for composite materials that may be damaged by thermal de-icing methods. Guidedwave is in the process of developing and testing ultrasonic de-icing technology in cooperation with the U.S. Air Force.

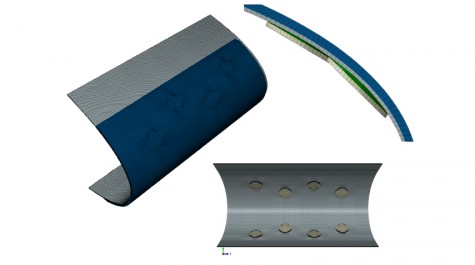

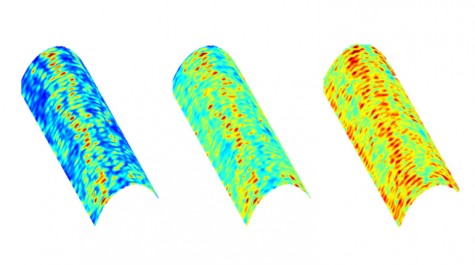

The ultrasonic de-icing technology utilizes piezoelectric actuators attached to the structure and controlled by a signal generator and amplifier system. The amplifier applies a sinusoidal excitation signal to the actuators, which causes them to vibrate and induce shear stresses at the interface between the ice and the structure’s surface. These stresses fracture and delaminate the ice to remove it from the surface. The ultrasonic de-icing system developed by Guidedwave utilizes advanced resonance tuning and actuator phasing and frequency sweeping algorithms to optimize the ice removal process while dynamically adapting to changes in the adhered ice mass and structural and actuator temperature.