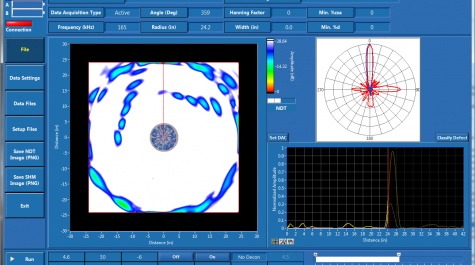

From a single position, the Guidedwave phased array plate inspection and monitoring system is capable of detecting wall thickness changes within a plate-like structure. The system incorporates multiple patent pending technologies. Phased array electronics are used to form an ultrasonic beam within the structure and then steer the beam around the plate, creating radar-like scans. This system is operated in conjunction with custom software and the Olympus UltraWave phased array platform.

Advantages

- Rapid assessment of large areas from a single position

- Detection of far side corrosion

- Ability to inspect under coatings and in hidden areas

- Not sensitive to liquids on either plate surface

- Advanced trade secret algorithms improve image quality and analysis

- Can be used for NDT or structural health monitoring (SHM)

- SHM can be performed on complex structure

Click here to learn more about the UltraWave phased array platform that is used as part of the guided wave phased array plate inspection system, or you may visit Olympus’ product page here.

Rapid Large Area Inspection from a Single Sensor Position: A Guided Shear Wave Phased Array Scan – Materials Evaluation

Guided Wave Phased Array Probes