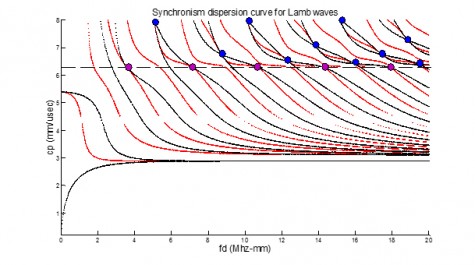

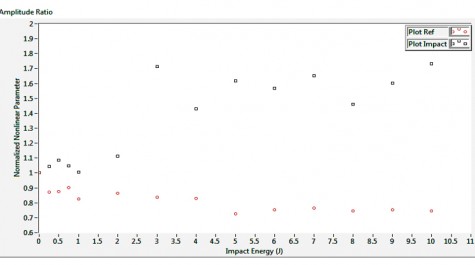

When guided waves are generated under certain excitation conditions, in addition to the traditional linear wave mode (known as the fundamental harmonic wave mode), a number of nonlinear higher-order harmonic wave modes may also be generated. Research shows that the nonlinear parameters of a higher-order harmonic wave mode have great sensitivity to microstructural changes in a material. Therefore, microdamage in the material can be detected and characterized based on the variations of the higher-order harmonic ultrasonic waves generated by the fundamental wave. This technique is referred to as nonlinear guided wave analysis.

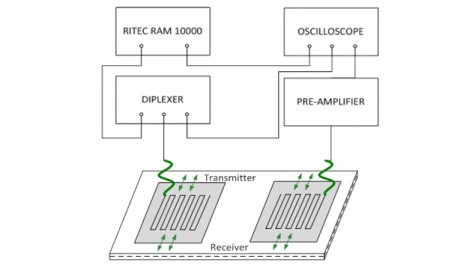

Nonlinear ultrasonic guided waves are known as one of the best approaches for characterizing changes in dislocation density and slip bands that precede the initiation of a fatigue crack. In nonlinear ultrasonics, signals that are sensitive to the microstructure of the material are received at frequencies different from the excitation frequency, while linear ultrasonic signals are only received at the excitation frequency. The linear ultrasonic guided wave at the excitation frequency can also be used to detect and characterize larger fatigue cracks. Guidedwave has worked with NASA and Penn State University to explore the applicability of the nonlinear guided wave technique to detect impact damage in composite materials with encouraging results. Research in this area is on-going and shows great promise for the future.