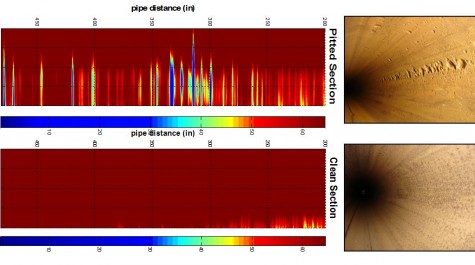

The leading cause of external pipeline corrosion is the disbondment of the pipeline’s protective coating. Unfortunately, state-of-the-art inspection pigs only have the ability to detect wall thinning and not disbondment. If the ability to efficiently detect disbonded coatings existed, it would be possible to alleviate the problem at its root, rather than waiting for metal loss due to corrosion. In addition to insuring the integrity of the pipeline, pre-corrosion disbondment detection would lower operational costs significantly as well as improve the safety of workers and communities in the vicinity of the pipeline.

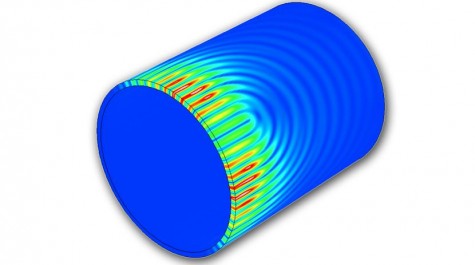

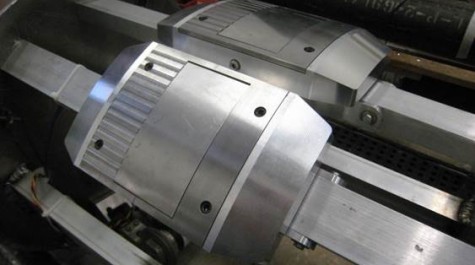

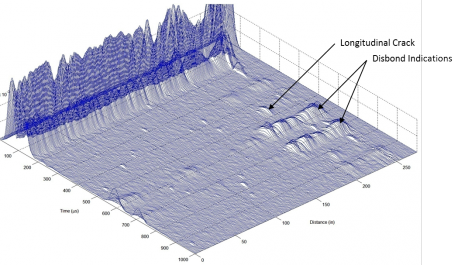

Because magnetic flux leakage is only exhibited in conductive materials, MFL pigs will not be able to detect polymer coating disbondment. MFL pig tools will have to incorporate a different technology in order to obtain pre-corrosion coating disbondment detection capabilities. Non-contact, EMAT generated guided wave ultrasound is a promising technology for the detection of coating disbondments. Guidedwave has developed a patented technology that uses circumferential guided waves to detect coating disbonds in pipelines with EMAT transducers that are fitted to an MFL pig tool. The system excites guided waves that are intentionally sensitive to the coating being adhered to the outer surface of the pipe to detect disbondment. This technology has also been proven to detect longitudinal cracks, which can be difficult to detect with MFL tools.